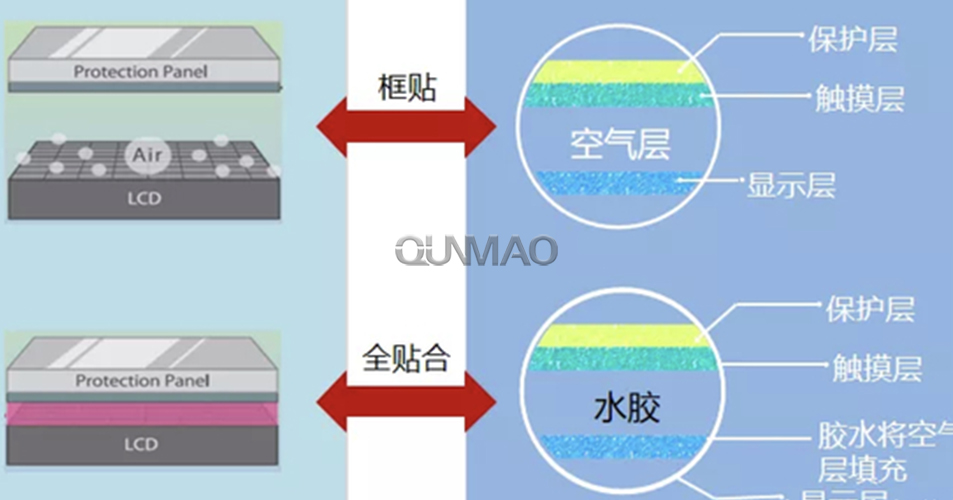

Conference tablets generally have two screens, the upper touch screen and the lower display screen. The method of gluing the upper and lower screens together is the lamination method. There are three bonding methods: full bonding, 0 bonding, and frame bonding.

Which screen bonding technology is better?

From a fever perspective, full fit has the best experience, but the cost is the highest. High-priced phones and iPads are fully fitted.

Of course, frame stickers are not as good as full stickers, but they are the lowest cost and highly cost-effective.

0Lamination is between full lamination and frame lamination

From a practical perspective, frame stickers are just fine. And just from the perspective of pursuing extreme fever, we can also harshly compare the three fitting methods.

Cost: Full Lamination >>> 0 Lamination > Frame Lamination

Experience: full fit > 0 fit >> frame fit

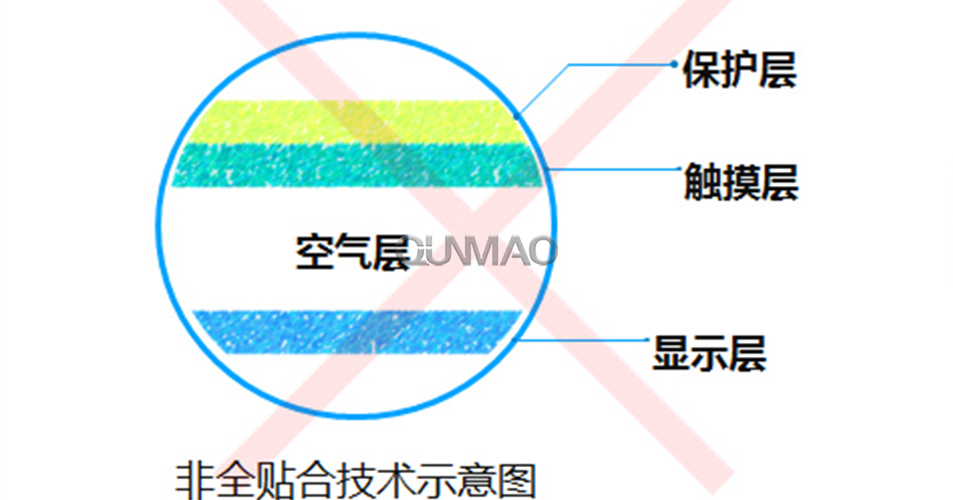

1. Frame sticker

Process: Use double-sided tape to stick the touch screen and LCD screen together on all four sides. The middle of the two screens is empty and has air.

Advantages: The process is simple, just apply a circle of glue, which is not easy to damage, so the assembly cost is low. The two screens are separated, and if one is broken, it will not affect the other, and the maintenance cost is also low.

Disadvantages: There is air between the two screens, so it is easy to reflect light and dust may enter. The two screens are separated, and the light from the display screen will be filtered together.

The one below is the frame-mounted screen technology, Qunmao conference tablet, the king of cost performance in the industry.

2. Zero fit

Technique: Use glue to glue the four sides of the touch panel and LCD screen. There is a transparent medium between the two screens, not air.

Advantages: Reflection is greatly reduced, the display effect is better, the body is thin, and no dust enters.

As a world-renowned display equipment provider, in order to provide participants with a better writing experience when operating,

Representative: Smart conference tablet, which adopts "zero lamination technology". On the one hand, the gap between the glass and the LCD screen is greatly reduced, thereby preventing light refraction from affecting the display effect, effectively improving the screen display effect, not missing any detail in the picture, and making the vision more transparent; on the other hand, participants touch The touch feeling is more natural when writing, which can restore the real handwriting experience, and the writing is more accurate, which can effectively meet the application needs of creative painting, calligraphy design and other scene fields.

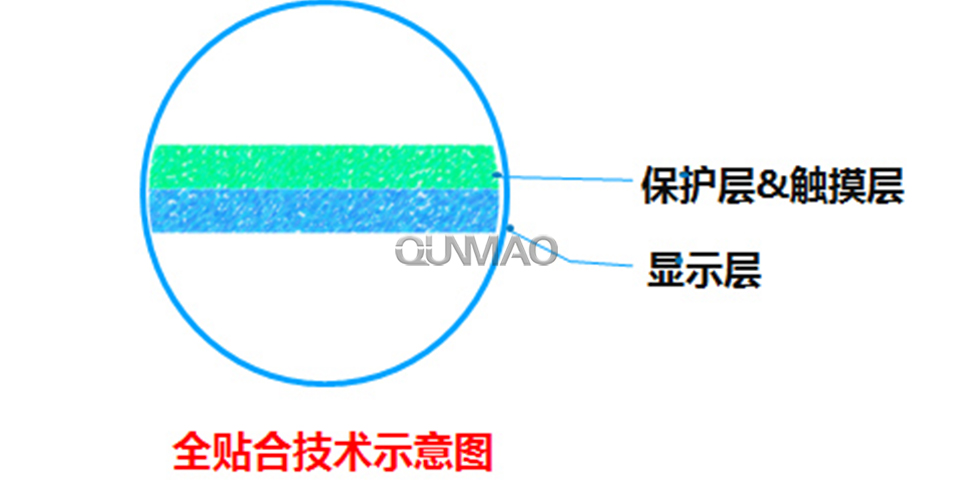

3. Full fit

Process: Use water glue or transparent optical glue to completely glue the touch screen and display together, just like a single screen.

Advantages: Reflection is greatly reduced, the display brightness is high and the effect is good, the body is thin, no gray enters, and the frame is narrower.

Disadvantages: High defective rate, so the cost is high.

From the perspective of practicality and cost-effectiveness: In fact, it is enough to pursue practical framed stickers. If you are looking for the ultimate experience, choose full fit. But the price is relatively expensive, because there is no need to use such expensive fitting technology at ordinary prices.

The most advanced full lamination process

At present, full lamination technology is mainly used in small-size products, including mobile phones and tablets. Currently, full lamination technology is basically used. However, in the field of large-size displays, the application of full lamination technology has not yet formed a large scale. The main reasons are that the process is complex, the production environment requirements are very high, the production yield is low, and the repair cost is high. These series of factors all affect the full lamination technology. The application of combined technology on large-size screens.

In the field of large-size full lamination, the nano smart blackboard has achieved a major technological breakthrough with a maximum size of 86 inches, a 178° ultra-wide viewing angle, seamless screen bonding, and no air or reflection. The adoption of the full lamination process fundamentally eliminates the air layer existing between the traditional display LED and the glass, making the LCD panel and glass closely adhere to each other to prevent dust and water vapor from intruding, so that the screen is always in excellent use. state. At the same time, it can reduce the reflection of external light, increase the transmission of the display screen and improve the brightness, thus making the picture clearer and more thorough. It can still provide excellent display effects under strong light or direct sunlight. In addition, the full lamination process allows the LCD screen and capacitive screen to fit perfectly, allowing for more precise touch operations.